| Print, video, sounds |

|

Aluminum cables and dead regulators

|

| |||||

|

I knew aluminum battery cables were a bad idea because I knew how many fires aluminum wire caused in houses. It was considered a serious fire hazard even back in 1980. Today the code still allows aluminum house wiring, but electricians are instructed to use an anti-corrosive coating, and to to torque the terminal to a very specific tight tolerance. To put a delicate marginal connection under the hood of a truck was a very sketchy proposition. An old-timer tipped me off to a report we could drag out every time the finance weasels suggested aluminum cables. The report detailed how the terminations of aluminum cable would just not hold up under salt-spray reliability. There were also problems with cracking, since aluminum will fatigue and crack. It turns out they do use aluminum cable in light aircraft. The only way this works is to clad copper over the aluminum strands. That way the terminations are copper-to-copper. Cladding is the way they make quarters out of very dissimilar metals. High nickel copper on the outside, pure copper in the middle. A professor told me the US Mint lays the three sheets together in a train flat car. Then they coat the top layer with explosives. They roll the train car into a cave and light the explosive on one edge. The explosion propagates, slapping the metal layers together. |

|

|

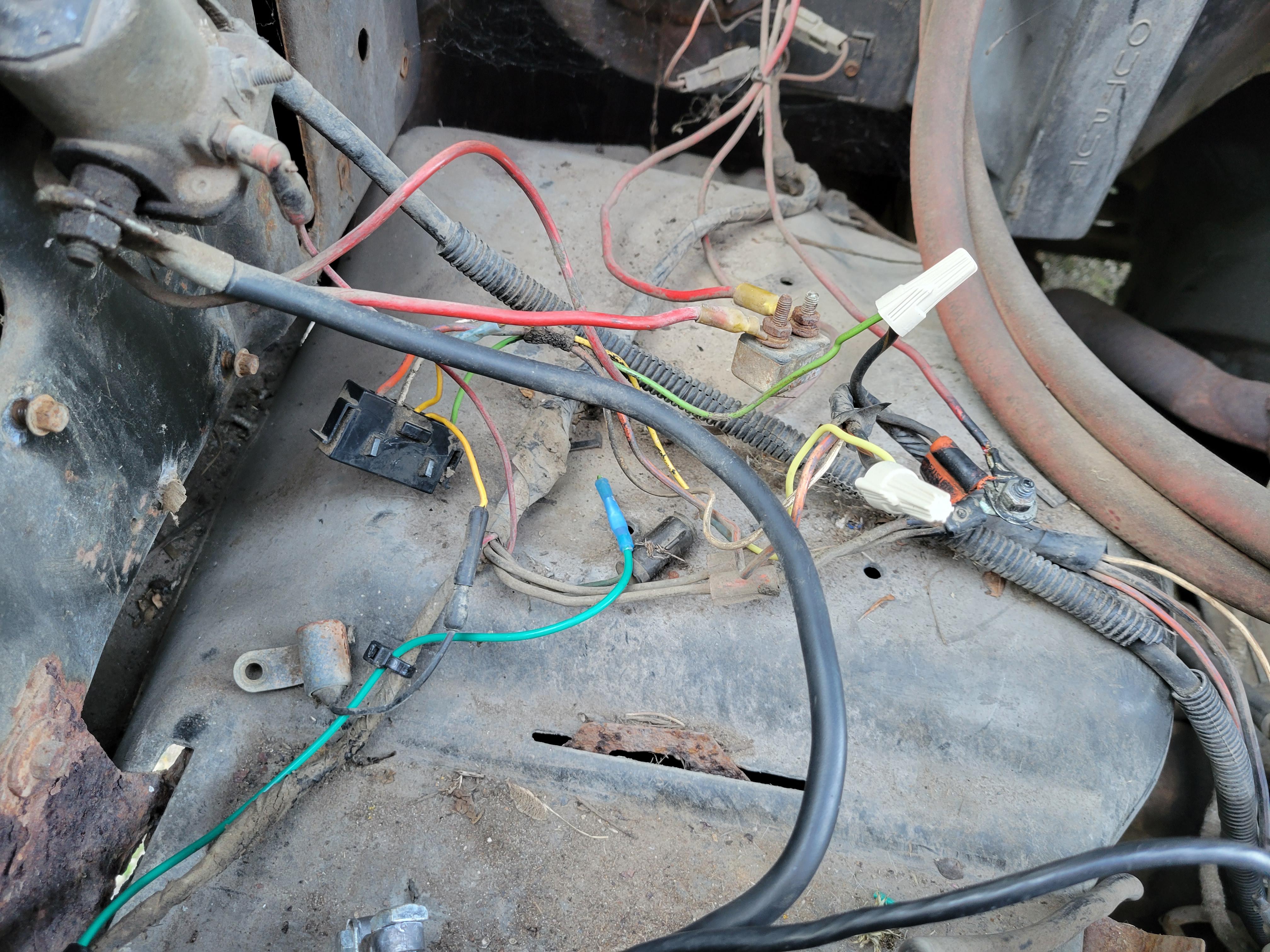

The brutal engine compartment of the 1980 Ford pickup, aluminum cables would die. Note the wiper motor location discussed in a previous article about another Ford disaster. Needless to say copper-clad aluminum cables are way more expensive than just plain copper. I sent the report to the Product Planner and never heard from him again.  Meanwhile, around this same time we got a report of a whole bunch of trucks boiling out the battery. Then the alternator would go full-voltage and destroy all the lights and electronics in the truck. We soon discovered that the voltage regulators in the trucks were good, but they had lost ground.  Here is a view of the fender where the voltage regulator mounted. The screws are where the regulator used to be. |

|

|

This post is in these categories: |  |

|