| A day-to-day strive |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

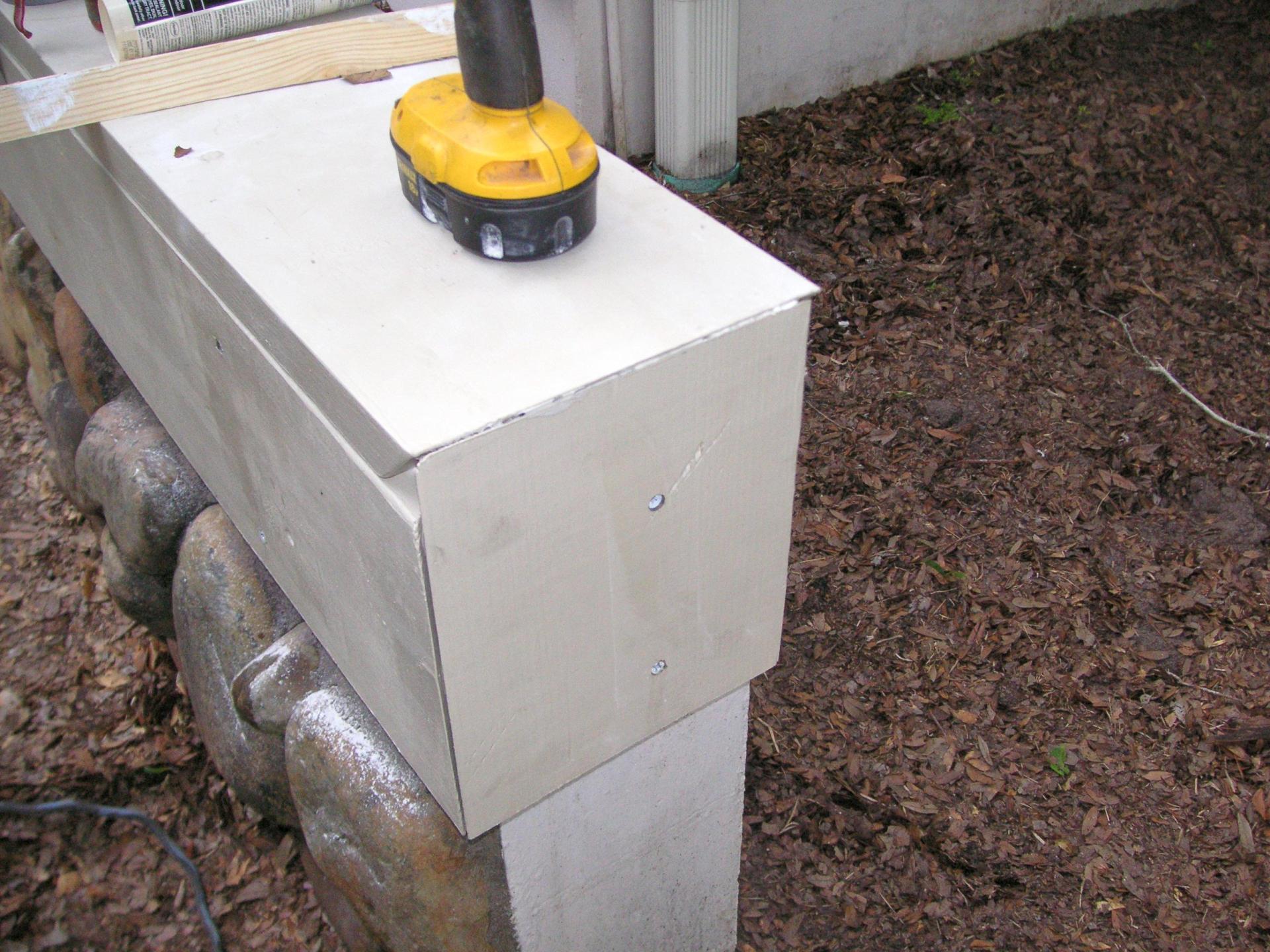

The end cap goes in properly and looks good.

The way I cut the lumber leaves this little hole in the corner. It was better than the way it was originally, with a diagonal cut on the top board.

I bought 5 tubes of caulk and used them all on the three walls. This old tube blew backwards.

|

|

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

CategoriesThe above posts arranged by date:

|  | ||||||

|