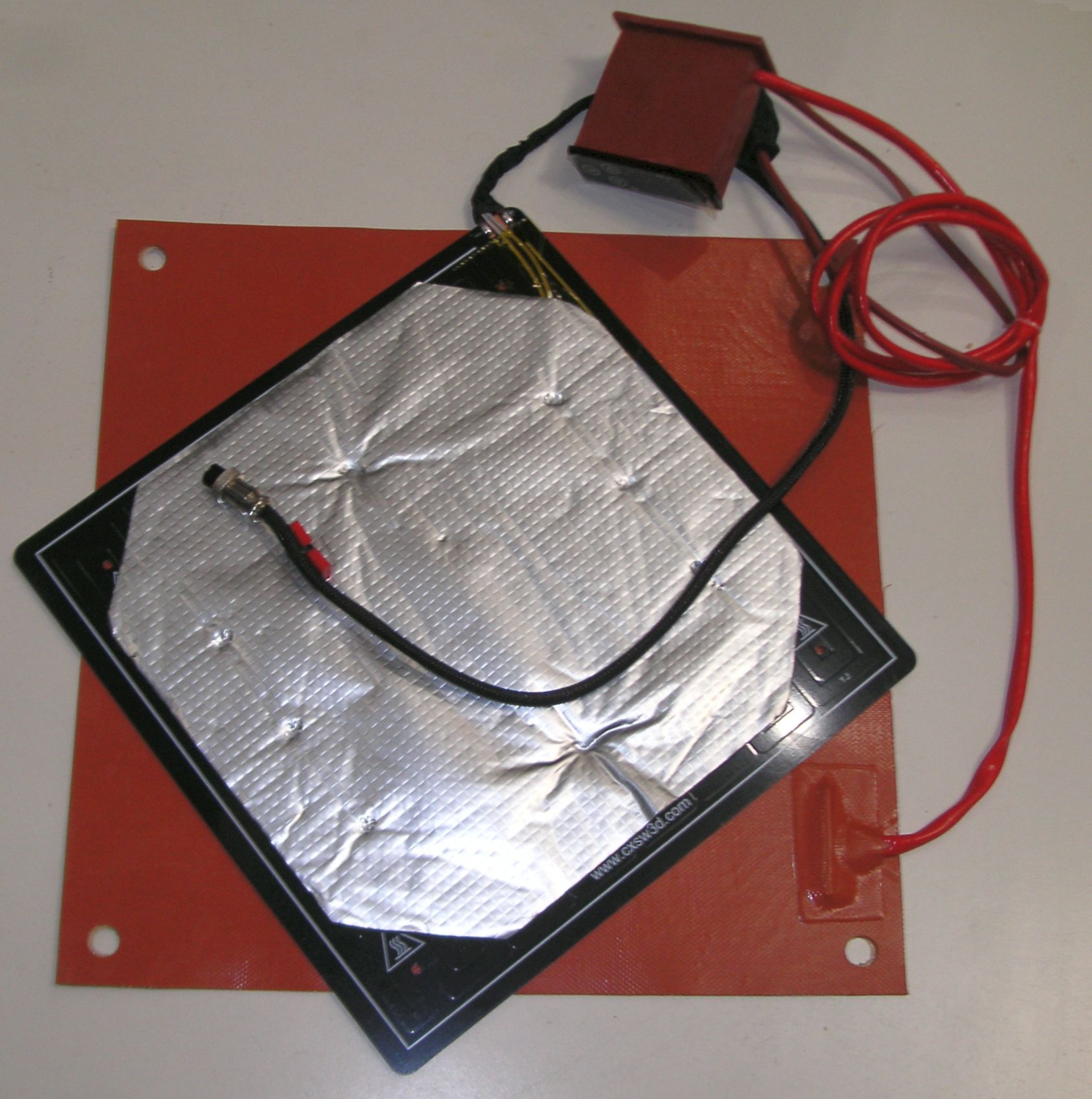

. The factory heater is the black and silver plate, laid on top of the first aftermarket heater I bought, which is still too small.

The original heater plugs into the CR10 control box. It is powered by the internal 12V power supply. It also has a sensing thermistor in the pad, that the control box can use to measure the temperature.

The after market heater plugs into the wall, and is much more powerful. It can get to target heat much faster, and it can produce a higher temperature. The high temperatures are useful for printing ABS and polycarbonate plastics. It comes with its own little control box. This means you have to set the temperature you want with this little box before you start your 3D print. This also means you have to "fool" the control box, which will try to read the thermistor which is no longer attached.

Usually you can set your sliver software to print at room temperature, and this will result in the G-codes running. Just be sure you have set the external box correctly before you print.

|

.

.